Center for Atomically Thin Multifunctional Coatings (ATOMIC)

December 02, 2020

As modern medicine becomes more personalized and less centralized, the need for scalable and tunable platforms for next-generation point-of-care biosensors remains an ongoing research objective. One promising technology for point-of-care analysis is electrochemical sensors, which are portable, ultrasensitive, and inexpensive. Electrochemical sensors are compatible with integrated circuit technology, enabling integration of sensors with the necessary electronic circuitry for data acquisition, processing, and transfer.

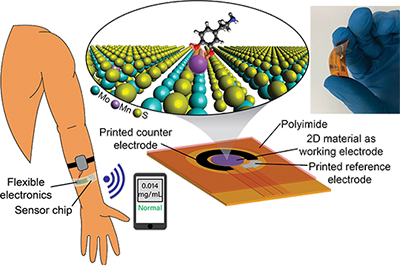

Two-dimensional (2D) materials, such as graphene, transition-metal dichalcogenides (TMDs), and their heterostructures, are viable candidates for fabricating electrochemical biosensors due to their tunable electronic properties and the abundance of functionalization strategies. Recent progress in low-temperature and low-cost synthesis of 2D materials through electrodeposition could allow such biosensors to be printed at high throughput on flexible substrates for integration in wearable technologies.

Researchers at Penn State Univ. (PSU) and Rice Univ. affiliated with the Center for Atomically Thin Multifunctional Coatings (ATOMIC), an Industry-University Cooperative Research Center, are exploring 2D materials for applications in electrochemical biosensing. Research at ATOMIC focuses on two key areas: scalable synthesis and sensor fabrication methods for electrodeposition of TMDs; and functionalizing 2D material inks for sensor fabrication on low-cost substrates (plastic and paper).

The researchers are modifying 2D materials via various physical and chemical routes to tune and improve the electrochemical response to target biomolecules, such as dopamine. Dopamine is an important neurotransmitter whose abnormal levels can be indicative of various neurological disorders, including Parkinson’s disease, Alzheimer’s disease, and schizophrenia.

A team of researchers led by Mauricio Terrones (PSU) and Aida Ebrahimi (PSU) has recently developed a low-cost detector for dopamine based on electrodeposited manganese-doped molybdenum disulfide (Mn-doped MoS2). The sensor enables detection of extremely low levels of dopamine — approximately 10 picomolar in buffer media.

In another collaboration between Air Force Research Laboratory (an ATOMIC industry member) and PSU, researchers investigated 2D material inks and their modification as a facile route for biosensor development. For example, they showed that by tuning thickness and morphology of graphene ink and its treatment under a specific low-temperature annealing condition, detection of dopamine down to a few picomolar can be achieved — the lowest reported concentration for sensors based solely on graphene.

Beyond tuning the surface properties, the researchers also showed that the response of electrochemical biosensors can be tuned based on the substrate. For example, they showed that sensitivity of iron sulfide-graphene heterostructures to reduction of hydrogen peroxide (an important small molecule involved in cell signaling and oxidative stress) depends on the underlying graphene’s doping type and level. The substrate properties affect the interface impedance and charge-transfer kinetics, which impact the sensor’s sensitivity.

Within the next five years, the ATOMIC researchers envision developing and expanding a variety of specific biosensors into a fully packaged sensory platform prototype. This platform would interface with a smartphone for remote control.

The research center’s long-term goal is to commercialize such a platform. Therefore, the researchers plan to seek direct input from key industrial partners on various aspects such as scalability, processing routes, and product design. Through this multipronged effort enabled by collaborations between university researchers and industrial R&D teams, the engineered sensors and integrated system can advance low-cost diagnostic technologies for applications ranging from wearable sensor arrays for human stress monitoring to smart cell-culture plates for high-throughput in vitro screening of drugs.

This technology was funded through the NSF Industry-University Cooperative Research Centers (IUCRC) Program.

This article was prepared by the National Science Foundation in partnership with CEP.