Advanced Mammalian Biomanufacturing Innovation Center (AMBIC)

November 18, 2020

Just like us, cells need to watch what they eat. For the first time, researchers studying cells used to create medicines like monoclonal antibodies—which can help treat cancer and autoimmune diseases—have found what goes into cells affects what comes out. Their results identified compounds that helped produce beneficial products and some that were too much of a good thing. Ultimately, this can help pharmaceutical companies manufacture drugs more efficiently.

“We found by limiting the choices that you give the cells—by changing the menu—you help the cells make healthier choices, and eventually produce the product that you're interested in,” said Maciek R. Antoniewicz, at the University of Michigan, and co-lead researcher on the project together with Michael J. Betenbaugh at the Johns Hopkins University. Their work was conducted with the Advanced Mammalian Biomanufacturing Innovation Center (AMBIC), an Industry-University Cooperative Research Center (IUCRC) funded by the National Science Foundation.

Increasingly, certain types of cells from mammals are being used to produce medicine. This method, which is a part of the new line of medicine known as biotherapeutics, can create complex proteins and other products that are impossible to make with traditionally synthesized chemical compounds. However, it is an expensive and time-consuming process.

Following the Breadcrumbs

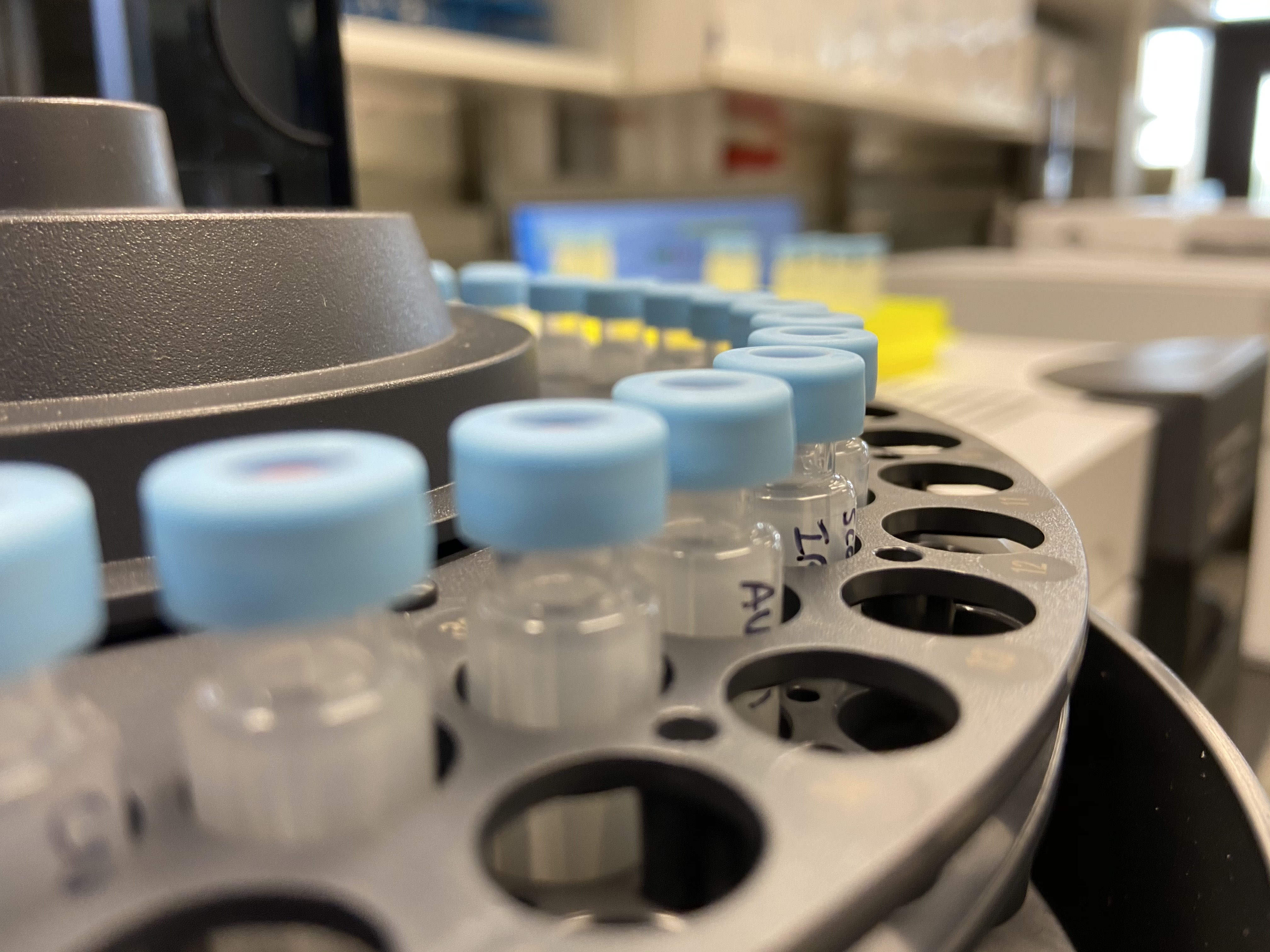

In biotherapeutics, cells are grown in a material called media. Before now, scientists didn’t know the specifics of how cells consume, or metabolize, the media. To study this, scientists tested two types of cells that are commonly used to produce products for medicine.

The researchers first marked different organic compounds, such as amino acids, with stable isotopes of carbon that are heavier than typical carbon atoms. This allowed them to track what the cells did with the compounds. They found some of the amino acids, when present in small amounts, were efficiently made into the medicinally useful products. But, when given too abundantly, they also created toxins as a by-product.

“We were surprised that some of these amino acids were metabolized inefficiently,” Antoniewicz said. “We came to the conclusion that there was quite a bit of room for improvement still in the composition of the media.”

Feeding the cells with the right compounds in the right amounts could help improve the cells’ production efficiency. Additionally, many cell lines have lifetimes of only a couple weeks. By removing the compounds that produce toxins as a by-product, the cells may be able to live an extra week longer, which could further improve their productivity. Combined, this will help drive down the costs of these biotherapeutics and help meet the global demand for these types of medicine.

Collaboration Yields Economic Impacts

The nutrient media used to grow cells are often pharmaceutical companies’ highly guarded secrets. The new project was possible thanks to AMBIC, which facilitated research and industry collaboration.

“The economic impact of medium development like this is enormous, as previous medium development efforts have been demonstrated to impact product quality and significantly increase cell productivity,” said Sandra Bennun Serrano, staff engineer at Regeneron Pharmaceuticals, who worked with Antoniewicz on the project. “As many of these projects require a high level of expertise and time commitment, they would not be feasible to pursue by individual companies.”

Similarly, the scientists agreed on the necessity of collaboration in the field. “We were fortunate enough that one of the sponsors of this project gave us a formulation for an older version of the media that they no longer sell,” Antoniewicz said. “This project simply would not have been possible without the close cooperation with these companies.”

In light of the new results, pharmaceutical companies will be able to update their media formulas. In addition to improving the cells’ diet, Antoniewicz and his colleagues are working on improving the cellular machinery itself through genetic engineering.